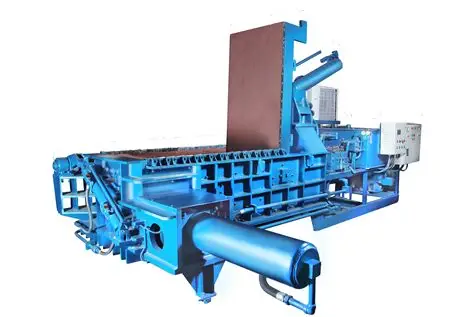

Hydraulic Scrap Bailing Press

At Dinesh Rubber and Engineering Works, we manufacture Hydraulic Scrap Baling Press Machines designed for efficient compression and recycling of metal, rubber, and industrial waste materials.

Built with a focus on power, safety, and productivity, our baling presses transform bulky scrap into compact, manageable bales — optimizing storage, transportation, and recycling efficiency.

With years of engineering excellence, our presses deliver high pressing force, robust structure, and smooth hydraulic operation, making them ideal for a wide range of recycling and industrial applications.

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Pressing Capacity | 30 Ton to 500 Ton |

| Bale Size | 200 mm × 200 mm to 600 mm × 600 mm (customizable) |

| Chamber Size | As per requirement |

| Operation Type | Manual / Semi-Automatic / Fully Automatic |

| Hydraulic System | Single / Double / Triple Compression |

| Motor Power | 10 HP to 75 HP |

| Production Rate | 2 – 6 bales per hour (depends on material type) |

| Material Type | Metal Scrap, Rubber Waste, Plastic, Paper, Cardboard |

| Frame Design | Horizontal / Vertical / Triple Action |

| Cooling System | Oil Cooling (optional for continuous operation) |

Key Features

Heavy-Duty Construction: High-strength steel frame for long-lasting durability and vibration-free operation.

Powerful Hydraulic System: Ensures uniform and high compaction ratio.

Custom Bale Sizes: Adjustable to suit storage and recycling requirements.

Energy Efficient: Optimized power usage with minimal maintenance.

User-Friendly Operation: Intuitive controls for quick cycle times and safe operation.

Flexible Configurations: Available in horizontal, vertical, and triple-action models.

Our Value Additions

Dinesh Rubber and Engineering Works adds value beyond manufacturing by delivering custom-engineered baling solutions that meet your exact material handling needs.

Our value-driven approach includes:

Tailor-made chamber and bale sizes for different industries and materials

Heavy-duty hydraulic cylinders for continuous operation under load

Efficient oil circulation and cooling systems to prevent overheating

Automated bale ejection and feeding systems for high productivity

Installation, maintenance, and operator training support

Applications

Metal scrap recycling and compaction

Rubber and polymer waste management

Paper, plastic, and cardboard waste processing

Automobile, construction, and foundry industries

Industrial recycling and solid waste management